Introduction

Craft production: Historic context.

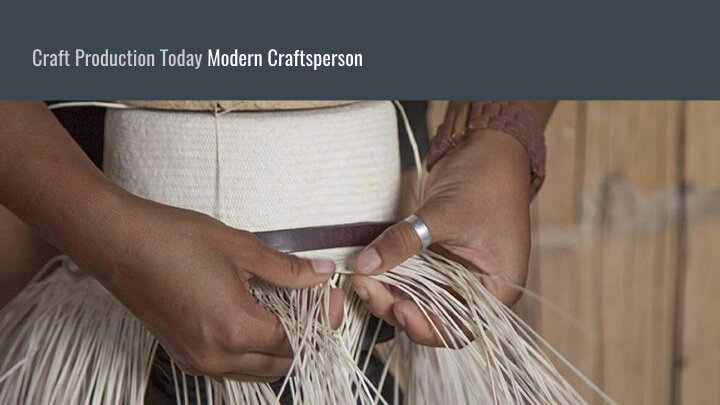

Craft production Today: Modern Craftsperson and Integration in Mass Production.

Or Craft Definition in historic context

“a productive process that involves skill, flexibility, creativity, choice, and knowledge accumulated over time, often through non-verbal experiential and observational learning, and embedded in a social context...The craft of textile production is a process through which techniques and objects are linked to the social coordination of labor.” (Textile production as craft in mesoamerica)

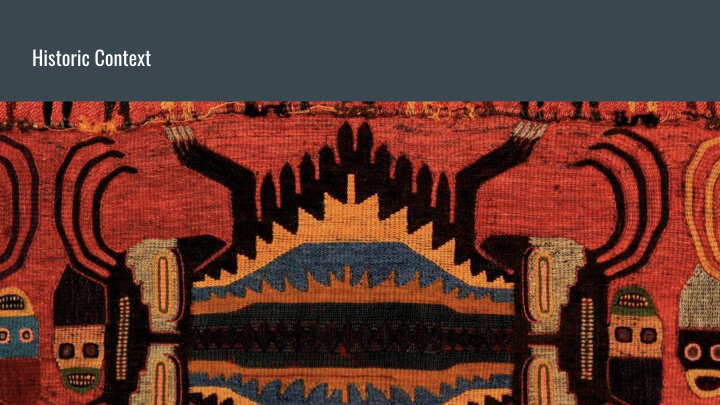

Embedded in the culture. Usually associated with gender depending on culture... Eg: Myan female deities shown participating in textile production. The craft like beliefs... is passed on through generations

Textile production was and still is done by a Combined effort, rarely done individually. Eg: Kimono production required a network of skilled artisans. that included spinners, weavers, dyers, embroiderers, specialist thread suppliers, stencil makers and designers

Textile craft producers fall into two groups: professional producers, where it is their only source of income; “Hobby” producers, which make textiles alongside another occupation

They can be classified as follows: Single producer who works from their home (Not necessarily mean they are the only ones to work on a specific piece) and Central location or cooperatives.

Not new concept: Like mentioned before, people have been working together for mutual benefits purposes and to improve product quality for centuries.Cooperative, as such, as a result of the Industrial Revolution.

Structure: individuals horizontal coordination to achieve vertical integration in their business activities.

Market contact: If you live in rural areas it can be hard to sell products. It is also important because isolation can cause neglect in-demand product trends.

Access to supply sources: If you are going to spend x hours on a project might as well use quality products. Purchase of small quantity at high prices.

Business training: training in managing their affairs.

Similar to those learned in product development…

Design related issues such as: Shortcomings in the development of new products and designs. Not having enough knowledge of the true tradition and heritage.

Management: Unmotivated teamwork and ineffective accounting and financial management.

Marketing: Poor market research and marketing techniques.

Production System: Inadequate planning, faulty task allocation, insufficient monitoring of production and poor time management.

Technology: Lack of knowledge of available new technologies, slow adjustment of production to new techniques, difficulty integrating technologies in craft production.

A different approach to selling handcrafted products.

Online platform includes the following features: Easy to set up a storefront and advertise, payment options and shipping labels and most importantly large customer base.. Over 20 million active buyers.

Joins the gap between sellers and manufacturers

Etsy requires factories to provide information about their production processes,subcontracting, labor practices, and willingness to collaborate with the company’s sellers.

Since policy changes in 2013, sellers can now work with manufacturers or other help in their Etsy shop. It also has a supportive community

Transparency is actually the vendor's responsibility, they like to constant remind us of this.

The following are examples of companies that integrate both.

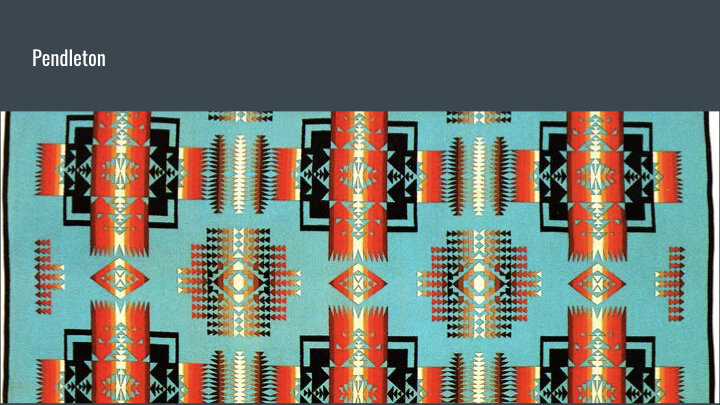

Oregon company famous for their “indian” blankets

Joe Rawnsley spent time with the local natives to develop preferences of color and design and manufactured these; the blankets were a success.

Native americans now produced crafts for trading (trading posts), where they would receive credit to buy mass produced goods (the blankets)

In a way aided the survival of craft in these and in return native americans still represent a solid 12% of their customers.

The reasons for preferring Pendleton’s blanket was the quality of the weave, brighter durable colors, not to mention the durability of the blanket itself.

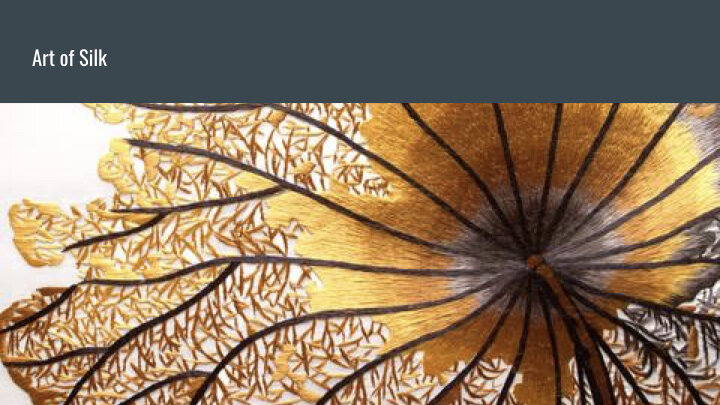

Embroidery company, started in 2011.

From traditional silk embroideries to machine embroidery. This an example of how luxury items can be down marketed through the use of technology.

They use of quarter silk thread in embroidery machinery, which probably operates slower.

An artisans working on the design would take a few months to complete the work. While it is not as labor intensive as someone manually doing it; it is still relatively (in terms of industrialization) time consuming.

It takes around a month to trace the embroidery to make it suitable for machine embroidery, after that there is machine set up time, followed by operator time and quality control (often done by an operator).

On a positive note once the designing and set up are done..replicas of the same design can be produced at a consistent quality.

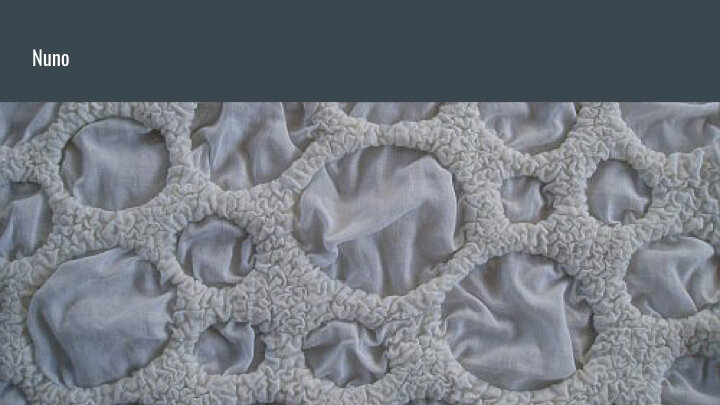

Japanese company that makes a variety of products; from installation pieces to clothing

The inspiration of these fabrics comes from different japanese crafts

Actually use a lot of traditional techniques. Referred to as "inappropriate technologies." by the founder

Dynamic response to the inevitable waste created through textile production. Collection form recycled leftover pieces from different project.